Maximize Your Fiber Optic Performance: Recognizing Optical Fibre Diameter Analyser Modern Technology

The performance of fibre optic systems is seriously influenced by the precision of their size, a factor typically neglected in the quest of optimum signal stability. Comprehending the innovation behind optical fibre diameter analysers exposes the complex balance in between measurement precision and production quality. These gadgets not only enhance compliance with industry criteria however also give real-time insights that can preemptively address possible concerns. The implications of their use extend past simple measurement; they can fundamentally alter the landscape of fibre optic performance. What elements should one think about to harness their full possibility?

Significance of Optical Fibre Size

The size of optical fibre plays an important role in identifying the performance and effectiveness of communication systems. It influences a number of crucial criteria, including the mode of light proliferation, depletion, and data transfer ability. Larger diameters typically permit numerous light settings, promoting higher data transmission rates. Alternatively, smaller diameters tend to sustain fewer modes, which can enhance signal clarity and reduce crosstalk.

Furthermore, comprehending the size's ramifications can lead to cost financial savings by lowering the demand for signal amplification and repeaters in considerable networks (optical fibre diameter analyser). In final thought, the relevance of optical fiber diameter can not be overstated, as it straight influences the total effectiveness and reliability of modern-day interaction systems

How Diameter Impacts Signal Quality

Signal quality in optical fibre systems hinges considerably on the diameter of the fiber. The diameter influences numerous key parameters, consisting of depletion, data transfer, and modal dispersion. A smaller diameter can bring about greater depletion prices, resulting in signal loss as light journeys through the fiber. This depletion can endanger the honesty of the transmitted data, bring about a decrease in signal top quality, especially over fars away.

On the other hand, larger sizes typically permit enhanced light capture and reduced modal dispersion, improving signal clearness. In multimode fibres, a larger core diameter can support multiple light modes, yet it might also present intermodal dispersion, which can weaken signal top quality. Picking the optimum fibre size is important for accomplishing the desired efficiency in details applications.

Furthermore, the communication between the fibre size and the wavelength of the light utilized plays an important function in figuring out the efficient transmission range and overall signal stability. Therefore, comprehending just how fibre size influences signal top quality is vital for network designers and engineers making every effort to enhance optical fiber systems for reliable, high-speed data transmission.

Overview of Size Analyser Technology

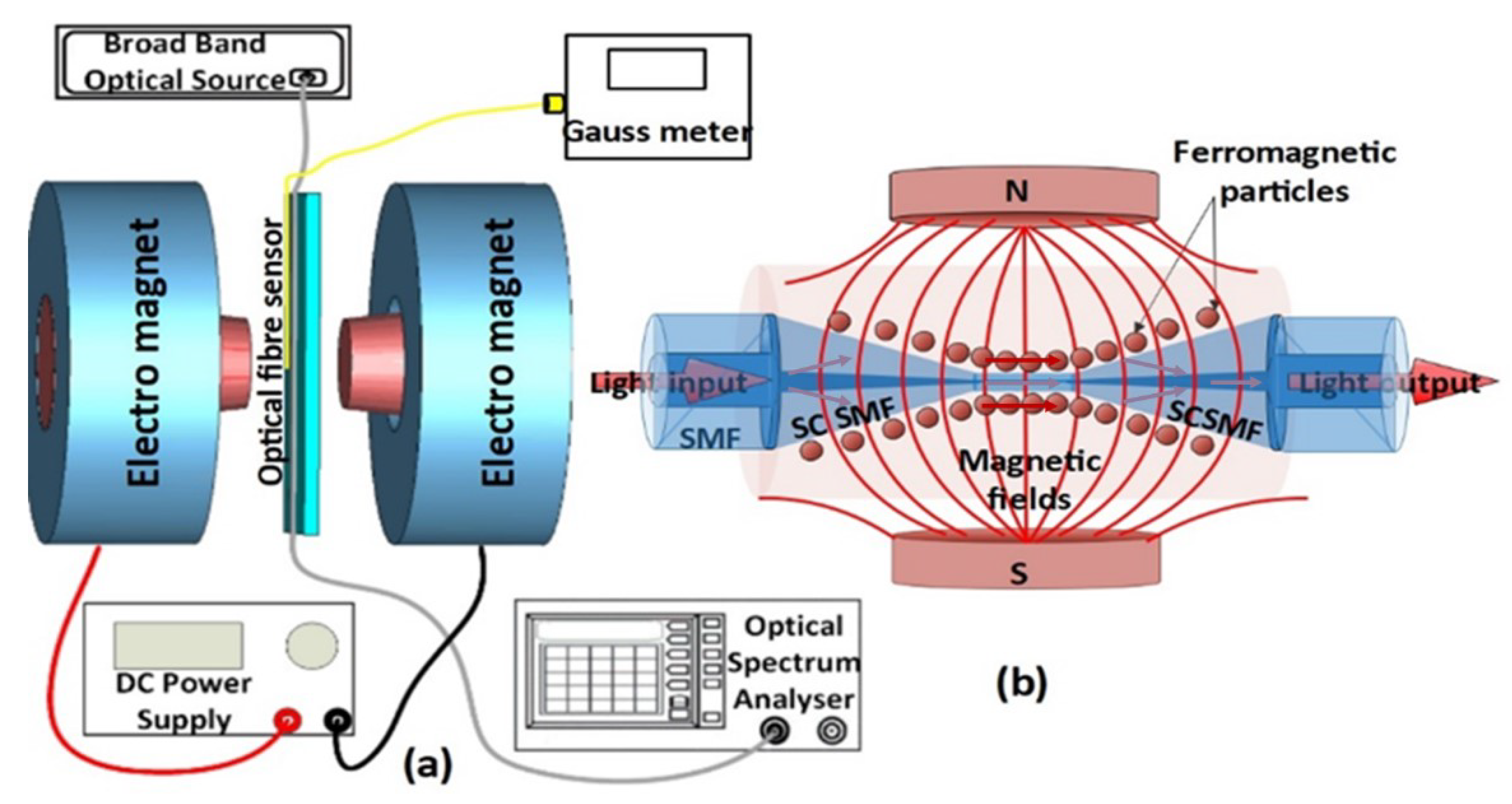

In lots of optical fibre manufacturing processes, precise dimension of fiber diameter is important for making sure regular efficiency and top quality (optical fibre diameter analyser). Size analysers are sophisticated tools made to analyze the physical measurements of optical fibres with high accuracy. They utilize advanced optical and laser innovations to gauge the size, ovality, and concentricity of the fibre, thus supplying critical data for quality assurance

These analysers can operate in-line during the production process or as component of off-line testing methods. In-line systems enable real-time tracking, permitting manufacturers to change specifications quickly, therefore keeping optimum production conditions. Off-line analysers, on the various other hand, supply thorough analyses of sets, making sure that any type of discrepancies from defined tolerances are recognized and resolved.

Size analysers dramatically add to the decrease of defects in optical fibres, enhancing total item reliability. By regularly measuring key parameters, these modern technologies assist in conformity with industry standards and specifications. As the demand for high-performance optical fibres remains to increase, the duty of diameter analysers becomes increasingly crucial in achieving the wanted top quality and efficiency standards in fiber optic systems.

Key Functions of Fiber Diameter Analysers

Although different versions of fiber size analysers exist, they frequently share a number of vital attributes that enhance their performance and integrity. One of one of the most considerable functions is high-resolution measurement capacities, which make certain specific diameter analyses, essential for preserving quality assurance in fibre manufacturing. Additionally, numerous analysers integrate advanced optical sensors made to discover minute variants in fibre size, hence supplying important information for procedure optimization.

Another vital feature is real-time monitoring, enabling drivers to receive instant comments on fiber size throughout the manufacturing process (optical fibre diameter analyser). This capability helps with fast adjustments and decreases the chance of issues. Numerous analysers likewise come furnished with easy to use user interfaces, enabling drivers to quickly navigate via setups and information outcomes

Additionally, durable information storage and analysis functionalities are necessary for tracking historical efficiency fads and guaranteeing compliance with sector standards. Some designs even supply connection alternatives for combination into existing production control systems, boosting overall functional performance. Last but not least, mobile and visite site compact styles enable versatile deployment within production settings, making sure that top quality guarantee processes are smooth and efficient. These features jointly add to the efficacy of fibre diameter analysers in optimizing fiber optic efficiency.

Finest Practices for Fibre Optimization

First, normal calibration of optical fiber diameter analysers is important. This ensures exact measurements and lessens possible inconsistencies that could impact performance. Next, preserving a tidy workplace is vital; dust and pollutants can bring about indicate deterioration.

Furthermore, it is essential to choose fibers that meet details application demands. This includes assessing variables such as depletion, data transfer, and ecological problems. Correct setup methods must likewise be followed, consisting of preventing sharp bends and excessive tension, which can endanger fiber honesty.

In addition, employing innovative monitoring systems can promote real-time efficiency analyses, allowing timely identification of issues. Routine screening and upkeep ought to be conducted to ensure that fibers continue to be within optimal operational criteria.

Last but not least, training personnel on the most recent fibre optimization innovations and methodologies will certainly enhance their ability to execute effective approaches. By adhering to these best practices, companies can considerably boost the efficiency and life-span of their optical fibre systems, guaranteeing effective communication and data transfer.

Conclusion

In verdict, the integration of optical fiber diameter analyser modern technology is essential for making best use of fibre optic efficiency. By making sure exact measurements of fiber dimensions, these analysers considerably improve signal quality and reduce losses during data transmission.

Signal top quality in optical fibre systems hinges dramatically on the diameter of the fibre.In several optical fibre production processes, accurate dimension of fiber diameter is essential for making sure constant performance and top quality. As the demand for high-performance optical fibres proceeds to rise, check this the duty of diameter analysers ends up being significantly vital in accomplishing the preferred high quality and performance requirements in fiber optic systems.

These features collectively over at this website contribute to the efficiency of fibre diameter analysers in enhancing fibre optic efficiency.

In final thought, the combination of optical fiber diameter analyser technology is essential for maximizing fiber optic efficiency.