Unlock Accuracy: The Ultimate Guide to Optical Fibre Diameter Analyser Equipment

Precise measurement of optical fiber diameter is essential for boosting the performance and dependability of fiber optic systems. As we check out these tools, it comes to be obvious that the future of optical fibre evaluation is developing rapidly, raising inquiries about how these advancements will certainly influence the sector.

Relevance of Optical Fiber Dimension

Accurately measuring optical fiber size is crucial in making sure ideal performance and dependability in interaction systems. The size of optical fibers straight influences their light transmission abilities, affecting bandwidth, depletion, and general signal stability. A precise measurement is necessary to maintain the wanted requirements for different applications, including telecoms, information transmission, and picking up modern technologies.

Incorrect or irregular fibre sizes can cause increased losses and reduced efficiency, ultimately compromising the efficiency of the entire communication network. Additionally, variants in diameter can cause problems in splicing and connecting fibres, resulting in greater operational prices and prospective system failures. As a result, executing extensive dimension protocols is essential.

Sorts Of Diameter Analyser Equipment

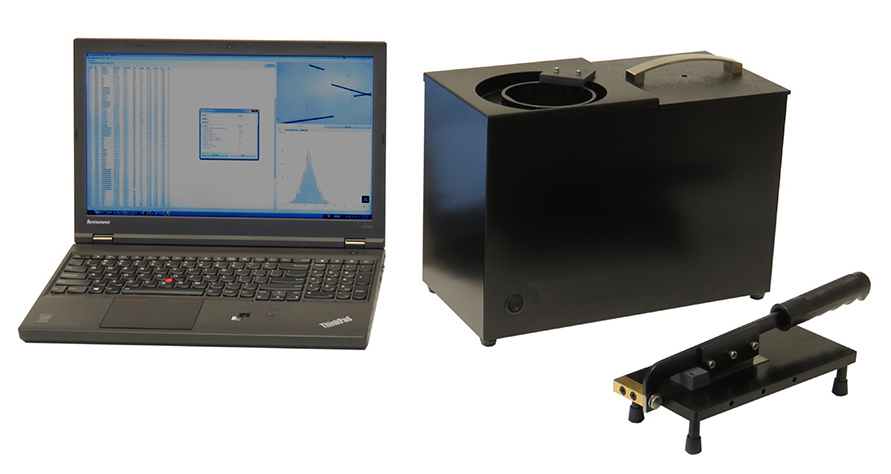

To accomplish trustworthy optical fiber dimensions, numerous size analyser tools are employed, each made to provide to details measurement needs and applications (optical fibre diameter analyser). These tools can be generally categorized into three primary kinds: guidebook, semi-automated, and totally automated analyzers

Manual diameter analyzers are generally used in smaller sized operations or research laboratories where precision is required but manufacturing quantity is low. They supply drivers straight control over the dimension procedure, permitting for mindful changes and confirmations.

Semi-automated size analyzers enhance performance by integrating hand-operated input with automated functions. These tools usually consist of easy to use interfaces that simplify the measurement procedure while still permitting driver oversight.

Completely automated size analyzers represent the pinnacle of dimension technology. These advanced systems integrate innovative sensing units and software application to provide real-time dimensions with minimal customer treatment. They are suitable for high-volume production atmospheres, guaranteeing consistent accuracy and rapid data collection.

Each kind of diameter analyser offers distinctive functional needs, making it vital for customers to very carefully review their certain demands when picking the proper tool for optical fibre measurement.

Key Attributes to Take Into Consideration

When picking an optical fibre size analyser, a number of crucial functions call for mindful consideration to guarantee optimal performance and reliability. Initially, dimension accuracy is critical; search for tools that offer high-resolution analyses, preferably in micrometers, to guarantee precision in diameter evaluation. Furthermore, the rate of measurement is important, particularly in manufacturing atmospheres where performance is necessary.

An additional vital function is the calibration process, as a dependable analyser ought to provide uncomplicated calibration procedures to preserve measurement integrity gradually. The array of diameters the tool can measure is additionally significant; make certain that it suits the certain fibre types appropriate to your applications.

Transportability could be a factor to consider, particularly for fieldwork; lightweight and portable designs enhance use in numerous settings. Furthermore, straightforward interfaces and software compatibility can assist in smoother operation and data evaluation.

Last but not least, think about the assistance and warranty used by the supplier; trusted client service and comprehensive guarantee options can safeguard your investment and ensure long-lasting fulfillment. By concentrating on these functions, you can select an optical fibre size analyser that fulfills your certain demands and enhances your operational abilities.

Best Practices for Usage

Efficient usage of optical fiber diameter analysers pivots on a thorough understanding of finest methods that improve measurement reliability and precision. First, ensure that the analyser is calibrated appropriately before each usage. Calibration against recognized requirements reduces potential errors and develops a standard for succeeding dimensions.

Second, preserve a clean atmosphere. Dirt, moisture, or contaminants on the analyser or the fiber's lenses can alter results. On a regular basis check and clean both the fibre and the tools to keep optimal performance.

Furthermore, perform dimensions at Recommended Reading consistent temperatures and moisture levels, as ecological aspects can influence results. Record each dimension meticulously, noting problems and any kind of abnormalities run into during the procedure.

Future Patterns in Optical Fibre Analysis

As the demand for high-performance optical fibers remains to climb, advancements look at here in evaluation methods are readied to change the industry (optical fibre diameter analyser). Future patterns in optical fiber evaluation will likely be driven by boosted automation and the combination of expert system (AI) and artificial intelligence (ML) innovations. These innovations guarantee to improve information accuracy, decrease analysis time, and allow real-time surveillance of fibre high quality

Additionally, the advancement of user-friendly and mobile analysis devices will facilitate on-site assessments, permitting higher versatility and performance in manufacturing environments. Improved imaging innovations, such as high-resolution imaging and spectral evaluation, are anticipated to give much deeper insights into fibre qualities, enabling suppliers to enhance their procedures better.

In addition, as markets significantly embrace sustainability, there will certainly be a promote green materials and methods in optical fiber manufacturing. This change will certainly necessitate brand-new analytical approaches to analyze the efficiency and longevity of these materials under varying problems.

Final Thought

Exact measurement of optical fiber size is crucial for maximizing efficiency and making certain dependability in interaction systems. Proceeded development will certainly even more improve the precision and effectiveness of optical fiber evaluation.

Precise dimension of optical Home Page fiber diameter is essential for enhancing the performance and dependability of fiber optic systems. In a significantly linked world, where high-speed information transmission is critical, the role of accurate optical fiber diameter dimension can not be overstated, as it serves as the foundation for robust communication infrastructure.When selecting an optical fiber size analyser, a number of crucial functions call for mindful consideration to ensure ideal efficiency and reliability.Efficient use of optical fibre size analysers hinges on a detailed understanding of ideal methods that enhance dimension reliability and accuracy.Precise measurement of optical fibre diameter is necessary for enhancing performance and making sure integrity in interaction systems.